| Type of project : | Hauts de France region call for projects STIMULE |

| Dates : | 01/12/2020 – 30/06/2023 |

| Research team concerned : | ER2 |

| Project manager : | Vincent DUBOIS |

| Centers concerned : | University of Artois |

| Partners : | Unité Transformations & Agroressources, ULR 7519, Université d’Artois, Equipe VAM2IN Valorisation des Agro-ressources en Molécules et Matériaux Innovants Unité Génie Enzymatique et Cellulaire, UMR-CNRS 7025, Université de Picardie Jules Verne Laboratoire de la Barrière Hémato-Encéphalique, ULR 2465, Université d’Artois Roquette Frères, Lestrem CODEM, Amiens |

Project description

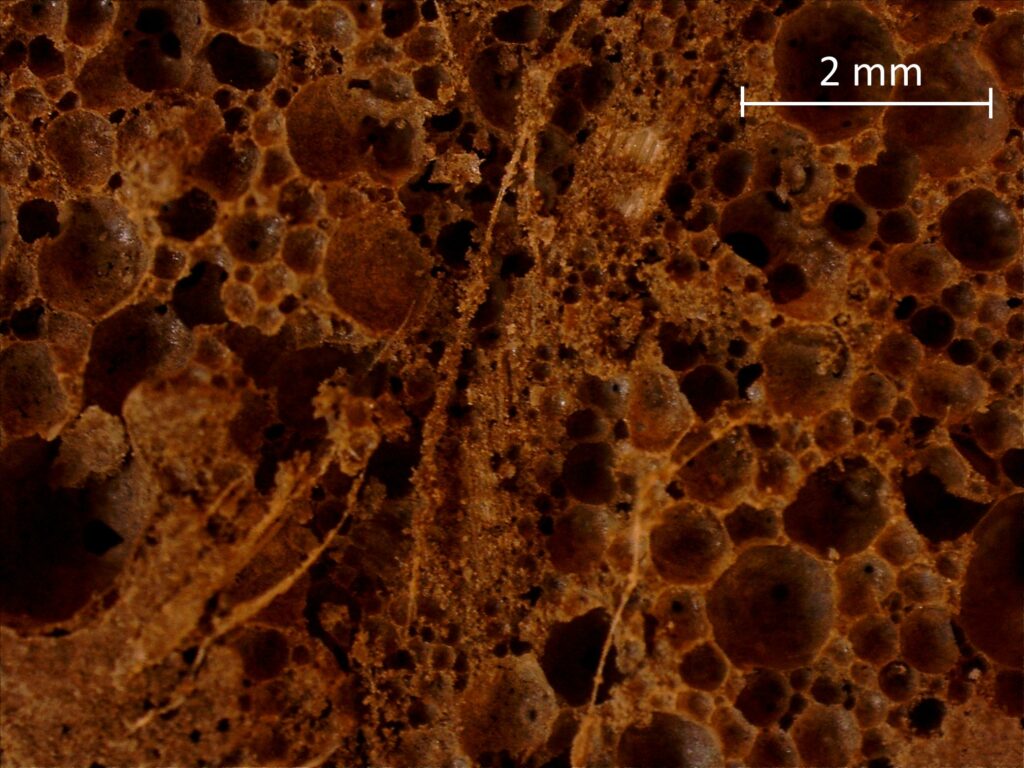

In the field of construction, the 2020 environmental regulations are based on E+ C- criteria to promote the construction of buildings that consume little or no energy with a low environmental impact, from the production of raw materials to demolition. The use of local resources from biomass is a response and would boost the local economic fabric, by promoting the development and structuring of eco-industries in the territories. In this context, the Civil Engineering and Geo-Environment Laboratory has developed an insulating foam made from flax shives. The porosity of the foam, which gives it its thermophysical properties, is achieved by a petro-based foaming agent. The amount of water incorporated during the production of the foam must be sufficient to promote foaming.

The objective of the project is to replace the petro-based foaming agent and reduce the amount of water entering the composition of the foam by developing a high water reducing foaming agent (HRAM). This AMHRE will be developed by UTA using co-products from the food industry and will have to meet the performance needs of the foam. Roquette will make some of its products available to study their suitability with the target foam. Key admixture properties influencing foam behavior will be identified. Threshold values will be defined to obtain the best performance of the foam in the fresh state (rheological properties) and after stiffening (thermo-acoustic performance, durability). The synthesis process will be optimized to promote production with low environmental impact. The harmlessness of the adjuvant vis-à-vis the people producing or using the product as well as the non-proliferation of fungi on the scale of the foam during the life of the building will be studied by the GEC and the LBHE.

Scientific contributions from the laboratory

The Civil Engineering and Geo-Environment Laboratory (LGCgE) of the University of Artois, project leader, will be in charge of the coordination between partners, the administrative follow-up as well as the foam formulation studies and the physical and mechanical characterization , thermal, acoustic of the formulas developed in order to validate or invalidate the biosourced adjuvants developed by UTA. The objective is thus to develop a foam with low environmental impact and high multi-physical performance.