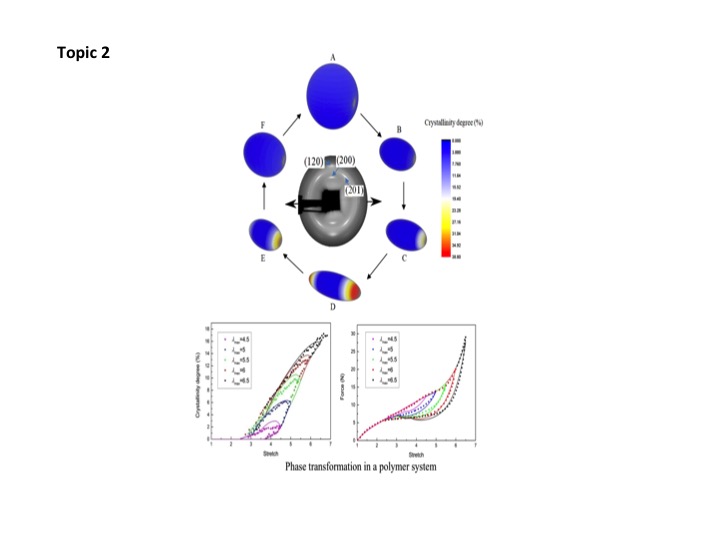

This topic is interested in all types of materials: massive homogeneous or heterogeneous materials, metallic, ceramic or polymers, coated or not. The main objective is the determination of their mechanical properties on local and global scales and the identification of their behavior laws in small and large deformations according to their properties. This theme is addressed with an emphasis on the relationship between modeling and experimentation. This is why, a first axis concerns the use of instrumented indentation for the mechanical characterization of materials. This approach makes it possible to consider a wide variety of properties and therefore to be interested in purely elastoplastic materials, such as metals and ceramics, or in polymeric materials for which the viscous aspect can be taken into account. With regard to polymer systems, an emphasis is under development and experimental verification of behavioral models and criteria of fatigue and rupture.

Mechanical characterization by multiscale indentation

Mechanical characterization by multiscale indentation

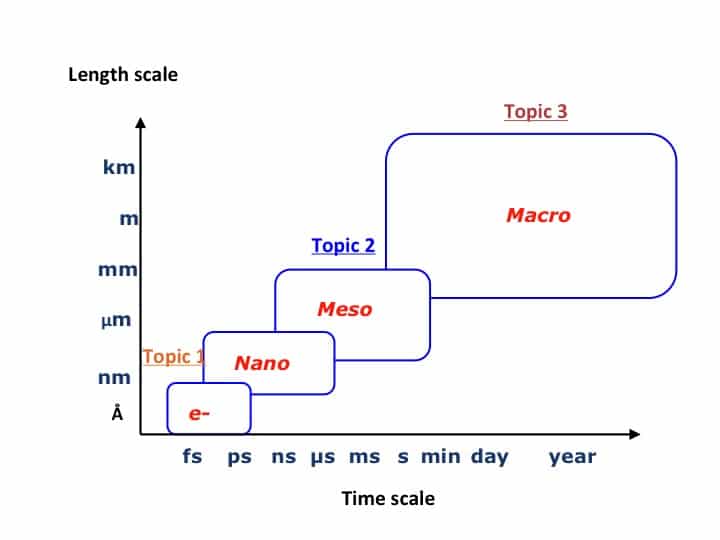

In general, we are interested in the mechanical characterization of materials, mainly by indentation, with a materials approach taking into account various parameters (multiphasic, heterogeneous, porous, coated ...) and an approach rather oriented towards the development of the technique of indentation. All measurement scales are covered, from nano to macro, different modes are used (classic, CSM and multi-cyclic) and different properties are studied.

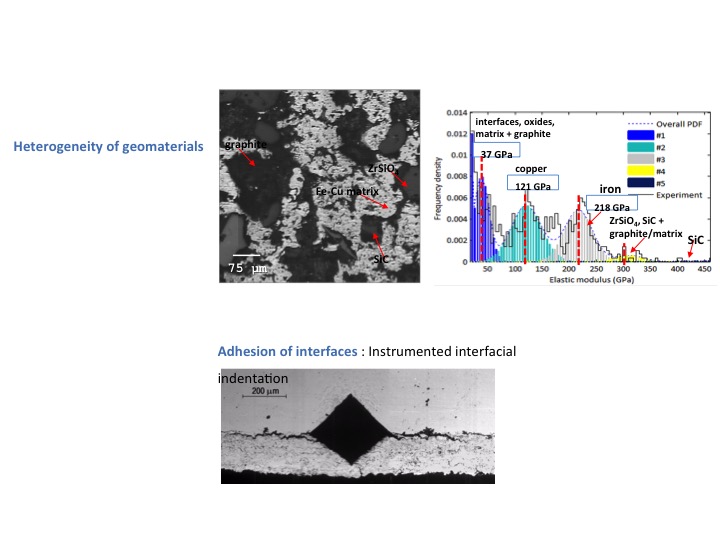

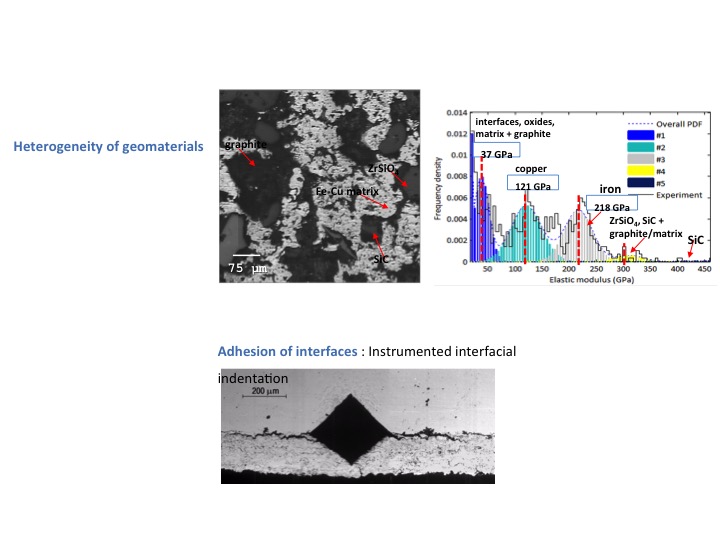

In addition to the mechanical characterization of materials, we are interested in the development of instrumented indentation at different measurement scales for the determination of mechanical surface properties. It is mainly a question of hardness but also of the modulus of elasticity, the toughness and the mechanical properties of traction by inverse methods, the laws of behavior in creep and in relaxation. Our goal is to deepen our knowledge of the methodology, its contours and its limits for obtaining reliable and relevant properties. This is why we are studying a wide variety of materials in massive forms with different mechanical behaviors (

from metals to ceramics), highly heterogeneous materials such as geomaterials (

concretes), materials coated with thin films (<10 μm) or thicker (some 100 μm), homogeneous or heterogeneous structures or materials with a gradient of surface properties obtained by mechanical or thermochemical treatments. This diversity of case studies has allowed us to make good progress on the knowledge of new materials. However, there are still scientific barrier to be overcome, such as the taking into account of experimental parameters (rigidity of the machine, tip defect ...), the effect of size in indentation, the modeling of the mechanical properties of coated or gradient materials and finally the search for relevant parameters to characterize highly heterogeneous materials such as those of civil engineering.

Mechanical characterization by multiscale indentation

Mechanical characterization by multiscale indentation